Biological 3D printing technology is developing at an amazing speed. We see that all functional organs and other complex tissues are built from scratch, and it is only a matter of time before they are transplanted to the patients who are in need. At present, researchers are continuing to study some of the technical problems that still need to be faced at various stages of the biological printing process. Recently, a research team in Osaka has made some progress in this field, and came up with a new way to stick the bio ink droplets together, that is, to use special enzymes.

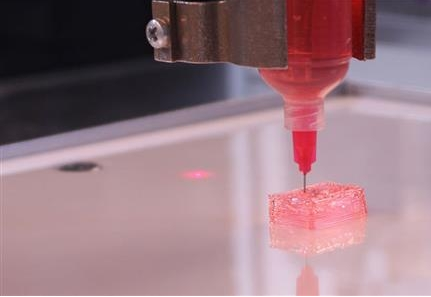

The improvement of biological 3D printing technology has greatly benefited all kinds of surgery and regenerative medicine. The most promising biologic printing method that has been proven to date is the use of special "bio ink", which is extruded to form a scaffold for organic tissue growth. The ink is filled with stem cells, which can be induced to differentiate in a specific way and form a specific type of tissue. However, it is still a challenge to balance the self adherability of the ink to its flow rate and the compatibility with a specific cell type.

Shinji Sakai of Osaka University is the main author of the paper entitled "dripping multi material biological 3D printing" through peroxidase mediated cross-linking, and is published recently in the Journal of macromolecular fast communication. According to Sakai, "printing any organization structure is a complex process. Bio ink must have enough low viscosity to flow through the inkjet printer, and when printing, it is necessary to form a highly viscous and colloidal structure quickly. This method can meet these requirements and avoid alginate. In fact, the polymers we use provide excellent potential for tailoring scaffold materials for specific purposes.

The team's innovation is the use of a special enzyme, horseradish peroxidase. This mediated hydrogelation process allows, in the presence of H2O2, the crosslinking between polymer addition of phenyl. The technology denies the demand for sodium alginate, a substance that sometimes causes the incompatibility of ink to some cell types.

The use of hydrogen peroxide is avoidable in the past, because it may damage cells, but by this way, the team ensures that the transmission of cells and hydrogen peroxide in separate droplets is carefully adjusted so as to limit their contacts and maintain cell survival. Their efforts were very successful, and in this way, more than 90% of the cells in the biological test gel proved to be feasible. Many complex test structures can also grow from different types of cells, which provides a direction for the implementation of technology in the more advanced process.

Shenzhen pineapple three-dimensional network Co. Ltd. is a new generation of 3D printing cloud platform, 3D is committed to providing printing services into life, with excellent technology and leading service platform, to create a new 3D printing Internet plus era, to provide one-stop professional 3D printing solutions for businesses and consumers, as well as the design building model, product processing and other value-added services, we hope that 3D can change the print life with inspiration.

| 中文

| sp@supomall.com

400 930 9098

| 中文

| sp@supomall.com

400 930 9098

| 中文

| sp@supomall.com

400 930 9098

| 中文

| sp@supomall.com

400 930 9098