3D printing and material increase manufacturing are the important industrial development direction of "China made 2025" by the State Council. One of the biggest features of 3D manufacturing technology is that it can give us a model that we can make many varieties, small quantities, or even personalization. There are many varieties, small batch and even individuation, but it does not increase the cost and does not reduce the production speed.

For this technology, the most important is equipment and materials. Therefore, with the support of policy, Xi'an established the Research Institute of increasing material manufacturing, and identified it as the manufacturing innovation center of domestic added material manufacturing. Of course, in addition to manufacturing, medical, architecture, and education are the areas of this technology that can play an important role.

Recently, a 3D Printing Industry Summit Forum sponsored by Beijing Fengtai science and technology park construction and Development Co., Ltd. has shared the specific application scenario of the technology in the industry. According to the sharing of experts and scholars from all sides, titanium media have compiled the following views.

Prosthetic devices print: more customizable, more secure

In the medical field, 3D printing can be used to print such organs as prosthetic eyes, teeth and so on, because of its high customability and without the need for molds. These are fully customized, can achieve Lidengkequ, if can increase the efficiency of just need to increase the printing equipment. At the same time, it can also form a certain scale, and maybe the future organ printing can also be made by App.

In addition to this print prosthesis, a more important use of 3D printing technology is the auxiliary programming operation. This is not to print a model so simple, it needs a certain degree of fineness, because it can provide more information to doctors, and carry out difficult operation planning. In the Department of orthopedics, this technology has been widely applied to the print head and print for fixed head guide.

The use of plaster in the past is now using a lightweight scaffold. The low temperature plastic plate can be well balanced with the compact and portable. For example, the support of cervical vertebrae is traditionally used as a sea surface. Now it can be personalized support with 3D printing. Burn patients will expand their scar in the past, and now it can be fixed with a tool to prevent scar spread.

Soft tissue surgery is also very active in this field, such as the mother and child splenic liver technology, without 3D printing, and the image number is difficult to support. With it, it is possible to know the anastomosis between blood vessels. The blood vessel relationship can be seen by 3D printing, which can reduce the damage to the unrelated blood vessels and direct the injury to the tumor.

Now the 3D printing model has been able to go from simple to complex. For this complex researcher, many organs have been tested, and materials that are almost the same with human skin and muscles have been developed. These printing organs can also be combined into a complete human body model to support the use of hospitals, especially for highly difficult surgery, such as the simulated human body in minimally invasive spine, in the general surgery simulation body, and the simulation body of interventional therapy.

In the dentist, the material used in the mouth of the patient has become the biggest problem: biological affinity, and antibiosis. Because the antibacterial in the middle of the mouth is very important. Something else in the oral cavity can cause other diseases. When it is corrected, it will cause damage to the teeth if it is not clean.

The equipment for making dental materials is mainly photosensitive resin, and all photosensitive resin materials imported in China are all imported. This resin requires low viscosity and low shrinkage. The shrinkage of the resin is particularly important in the application of the oral cavity. The domestic exploration has begun in this area. At present, the researchers, through the regulation of the resin formula, made a homemade resin close to the resin and added a silver - carrying antibacterial agent.

In the field of 3D printing, all countries lack the laws and regulations in the field of medical application. They are groping for different stages. However, the application of this technology in the medical field has been highly valued by all countries, and they are promoting the construction of laws and regulations in the field of technology application and medical care. In December this year at the beginning of the month FDA officially released the technical material manufactured by technical considerations, the guiding principle is equivalent to the China technical review, which is particularly detailed to 3D printing technology, taking into account the risks and requirements, very detailed.

The importance of standardization is beyond doubt. First, the standard is established, the industry is based on the basis, and the review is also available. At this stage, there is a special lack of quality standards for 3D printing in the medical field.

Construction industry: preliminary exploration stage

The history of human architecture started from stone and wood. In modern times, the mainstream reinforced concrete structure was built. It was built on the basis of steel structure and glass structure in 20s of last century. So is it possible for a building to be printed out?

There are many construction firms and construction companies using 3D printing manufacturing technology, architectural design project, the key like steel structure, connection structure and special custom, wall panel and so on, the overall design of print building, to expand its scope of application is more and more widely.

At present, within the world, the 3D printing architecture is in a very preliminary exploration stage. There are many problems in it, and the most important one is the material problem. At present, there are some problems in the strength and safety of the printed concrete. The best performance of a concrete material is to be pressed, to withstand pressure, not to collapse, but not to bend - it is based on steel.

It is impossible for the 3D concrete to print out the steel bar and only print out the concrete. This is its biggest defect. Either the steel bar is put up first and the concrete is printed, or, on the contrary, it is first printed and then inserted into the steel bar. This is not far from the way our traditional architecture is.

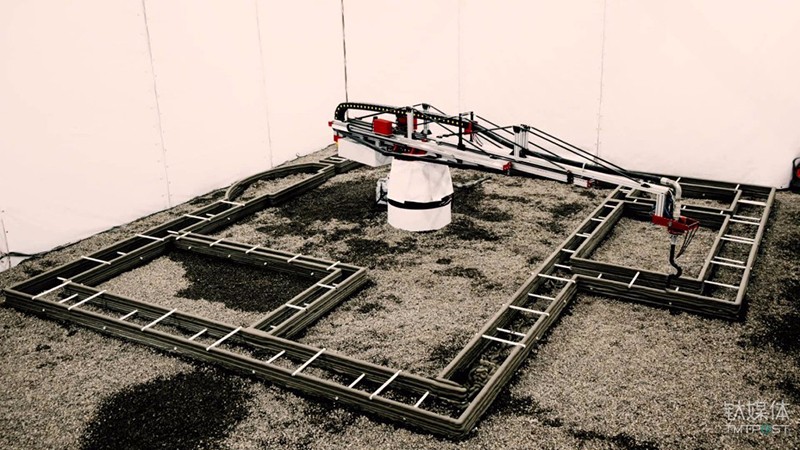

At present, the international has begun to explore the need of no steel to support, and can achieve such a functional material. Nanoscale concrete is the answer to the present. Intelligent printing based on the way, through the material, but also can realize the multi dimension print, it can print a variety of different forms, to meet the individual needs of the form, through the arm to realize multidimensional air print, there are more ways to solve these problems, the construction of houses, the irregular shape will become possible.

Housing is a system, which contains various structures. It needs to go through various processes, such as waterproofing, thermal insulation, decoration and so on, so that we can combine them into one, so that we can achieve housing construction and eventually go to building industrialization. The most important thing is what kind of equipment is used when the house is printed. Now, when building structures by 3D printing, regardless of size, they need door frame and print heads. If a layer is made of two layers, the frame can be made through structure. If you want to print a tall building, or print a higher building, the door frame is very high, and it needs to be mechanically possible.

3D printing and binding casting: reduce costs, increase strength

Look at the ancient casting has a long history in Chinese, first ingot is then to play, but not to finish forging, forging repeatedly. Repeated forging can eliminate the defects of the casting and make the grain finer and even. The same is true of modern technology, and it also needs to be heated continuously to ensure that the metal is in a forgable state.

The process of open processing is very high in heat consumption and is a heavy pollution process. The way of production is universal in the world. After casting and forging, the process is very long. Repeated forging and heating are energy consuming and heavy polluting. Under the trend of overall lightweight manufacturing, relying on large forging machines and larger and larger (8-15 tons) investment is huge. In the first place, the ingot, including the size of the parts, the final parts should be cut off many parts, especially in Aeronautics and Astronautics, the material utilization rate is very low. At the same time, a part needs different materials according to different functions.

3D printing technology can shorten the production process, but it is the biggest obstacle in industrial application, is its own defects, without casting forging, the performance and the possibility of difficult and forging, inhibition of deformation and fracture is difficult, and the current efficiency is less than the traditional process, the cost also drops.

Break through technical defects in its way is to change the way of making the domestic manufacturing of casting and forging separation, to achieve one side edge melting casting and forging, forging. With a equipment, wire and small pressure to get forgings to realize the green manufacturing of short process, single machine light load and energy saving. Solve the problem of traditional casting can along the contour digital forming, forging and milling integrated digital realization. The past needs a long process, the equipment of casting and forging, now only one input wire can be obtained.

In the past in the process of casting, casting and forging parts in common cooling process, very easy to crack, yield less than 10%. This technology can be done one hundred percent, and there is no defect. The development of thousands of years of casting and forging combined with 3D technology, printing technology, reborn.

3D printing technology can also be used in the stamping moulds of the car wing panels. This mold realizes the mold surface as mould steel, and the internal part is cast steel, which greatly reduces the cost. Most of them are made of general materials, and a few of them use very good materials. Not only is the mold, but the material is very expensive, only on the material has an overwhelming competitive advantage. The 3D printing innate crystal is transformed into a uniform equiaxed fine crystal, and the shape and quality are created in parallel, and the performance exceeds the traditional forgings.

3D printing is a technology field highly dependent on materials and equipment. The development of the whole industry depends largely on how to find materials that are cheaper and easier to use. In the early stages of industry development, 3D printing should be subtracting, focusing on several areas to develop more. At the same time, it is necessary to use industrial means to solve the problem of individualization, making the 3D printing industry a normal industry and a promising industry.

Last but not least, 3D printing is still in the early stage of development. It has not yet established effective standards in many areas. It takes some time to explore and practice.

| 中文

| sp@supomall.com

400 930 9098

| 中文

| sp@supomall.com

400 930 9098

| 中文

| sp@supomall.com

400 930 9098

| 中文

| sp@supomall.com

400 930 9098